Waterproof Power/Data Transmission Connector

RK series power waterproof connectors are high-reliability, multipurpose connectors, compatible with LP series, and mainly used for power and signal transmission in harsh environments. It has a waterproof design to ensure connector stability and reliability in harsh environments. The connectors are waterproof, dust-proof, shock-proof and high-temperature resistant, suitable for a variety of outdoor environments and industrial applications. In addition, this series of power waterproof connectors also has the advantages of being easy to plug and pull, reliable contact, corrosion resistance, etc., and is a cost-effective connector.

According to the panel installation size, it can be divided into RK12 (12mm) series; RK16 (18mm) series; RK20 (22mm) series; RK24 (25mm) series.

How to choose

Standard Type

(Male Plug +Female Socket)

Reversing Type

(Female Plug +Male Socket)

Docking Type

(Male+Female Cable Plug)

Product Dimensions

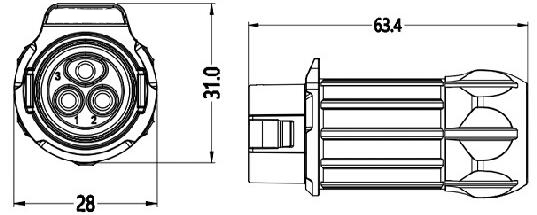

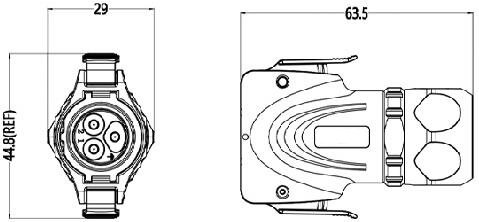

Docking Cable Plug

Plug

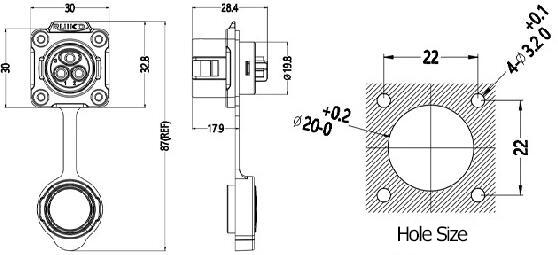

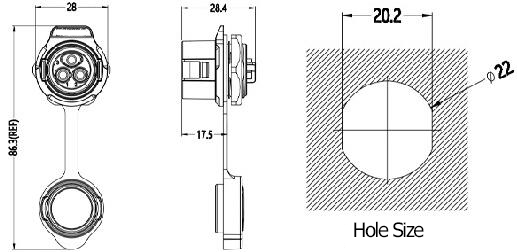

Flange Socket

Bulkhead Socket

Application

RK series waterproof power and data connectors are ideal for waterproof, dustproof and corrosion-resistant applications such as outdoor lighting, LED displays, solar photovoltaics, power tools, electric vehicles, marine vessels, marine engineering, petrochemical and other sectors.

- New energy fields: photovoltaic systems, servo motors, e-bikes, inverters and solar chargers.

- Automation equipment: mobile robots, automated warehouse handling systems and torque transducers.

- Communication systems: disinfection robots, vehicle monitoring systems and monitors.

- Lighting: horticultural LEDs, stage lighting, streetlights, LED video walls and landscape lighting.

Industrial Automation

Solar Photovoltaic System

Communication Equipment

LED Plant Growth Lamp

LED Display Screen